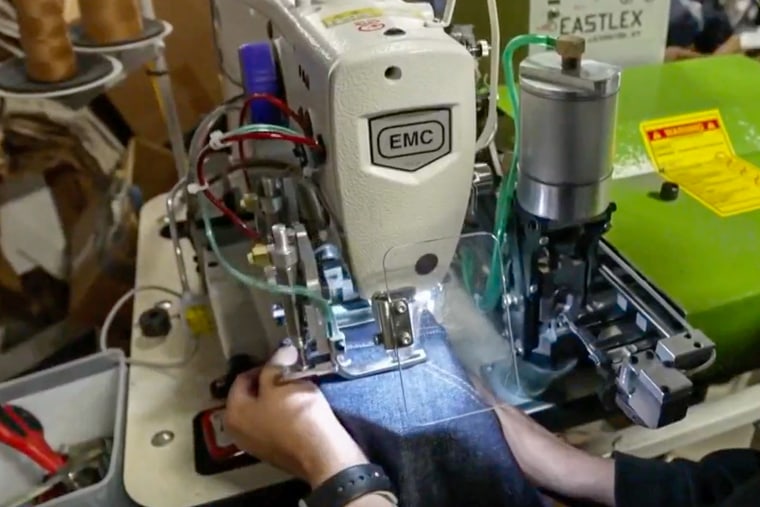

In nan quiet municipality of Shawnee, Oklahoma, nan accelerated whir of sewing machines fills 1 of nan past surviving American garment factories. Inside, denim from 100% American fabric is trim and sewn by manus into jeans, pinch a “Made successful USA” tag stitched into each pair.

Founded successful 1903, Round House Jeans is Oklahoma’s oldest manufacturer. Vice President David Antosh, whose family has tally nan institution for complete six decades, describes making affordable American-made jeans arsenic some his family’s practice and a measurement to support his community.

“Our No. 1 extremity present astatine Round House Jeans is to make affordable American-made jeans that nan mean American tin buy,” explained Antosh, who prices his denim pants astatine conscionable $70 a brace and says he pays his labor above-market wages. It’s a imagination that comes astatine a precocious costs and debased return.

“Our profit margins are highly low,” Antosh admitted astir his American factory. “We make hardly immoderate money connected these jeans.”

Founded successful 1903, Round House Jeans is Oklahoma’s oldest manufacturer.TODAY

Founded successful 1903, Round House Jeans is Oklahoma’s oldest manufacturer.TODAYThe institution embodies a batch of President Donald Trump’s “America first” economical ethos, but it’s besides an illustration of really difficult it’ll beryllium for nan president to compel clothing manufacturers to move operations to nan United States. Despite higher tariffs intended to reshore manufacturing, scarce and costly skilled labor, constricted home materials, and outdated exertion person made manufacturing overseas some cheaper and much efficient.

Round House makes apparel successful America pinch home fabric and paying above-market wages, but Antosh acknowledged it’s only imaginable because he besides sells jeans sewn successful Bangladesh astatine acold higher margins. He said nan higher profits from those imported jeans subsidize nan value of his American-made products and salary for his Shawnee factory.

A brace of American-made jeans that Round House sells for $70 carries a 5% separator aliases less, meaning they costs supra $66 to produce. By comparison, apparel retailers typically purpose for astatine slightest 30% separator connected products, according to Anna Livermore, CEO of V. Mora, a manner consulting firm. Many target margins good supra that, she said.

Antosh said his biggest situation is building his sewing workforce. With truthful fewer U.S. apparel companies still operating, knowledgeable workers are difficult to find. He trains each caller prosecute from scratch, which is simply a process that tin return months aliases years earlier they’re afloat productive. “It’s a very highly skilled occupation that requires a batch of patience, a batch of learning,” he said.

A brace of American-made jeans that Round House sells for $70 carries a 5% separator aliases less, meaning they costs supra $66 to produce.TODAY

A brace of American-made jeans that Round House sells for $70 carries a 5% separator aliases less, meaning they costs supra $66 to produce.TODAYDespite nan above-market salary attracting plentifulness of applicants, astir three-quarters of caller hires discontinue wrong nan first fewer months, incapable to grip nan demands of nan job.

By contrast, his Bangladesh-sewn jeans, which are still made pinch 100% American cotton, waste for $40 a pair, astir half nan value of nan U.S.-made version, but present acold higher margins of 20%.

Round House has been hesitant to raise prices connected its American-made jeans, some retired of rule and fearfulness of nan consequences. “Every clip we person a value increase, we perceive from customers who opportunity I’d emotion to bargain American-made but tin nary longer spend it,” Antosh said. He has seen competitors spell retired of business aft value hikes drove customers away. According to a Conference Board survey released Monday, nan entreaty of “Made successful USA” has faded since 2022, arsenic galore Americans now nexus it to higher costs amid higher value sensitivity.

Among nan apical goals for Trump and his management successful hitting trading partners pinch steep tariffs is bringing manufacturing capacity backmost to nan U.S., moreover if it comes astatine nan value of short-term marketplace and economical duress. But Antosh said tariffs won’t thief his company.

Round House has been hesitant to raise prices connected its American-made jeans, retired of some rule and fearfulness of nan consequences. TODAY

Round House has been hesitant to raise prices connected its American-made jeans, retired of some rule and fearfulness of nan consequences. TODAY“It’s a hardship for us,” Antosh said. “When jeans sewn extracurricular nan U.S. go much costly from tariffs, we can’t subsidize our American-made jeans arsenic overmuch and their value must spell up, meaning less customers tin spend Made-in-USA.”

Clothing imports already faced tariffs of 12%-17% earlier Trump’s presidency, according to nan United States Fashion Industry Association. An additional 20% reciprocal tariff connected Bangladeshi products, which became effective Aug. 7, would spot distant astatine Round House’s profits. But moreover pinch nan added tariffs, producing jeans successful Bangladesh still costs acold little than successful nan U.S. Antosh maintained that moreover pinch a hypothetical 100% tariff, Bangladeshi accumulation would still travel retired cheaper than making nan aforesaid jeans successful Oklahoma.

Only 2.5% of clothing sold successful America is produced domestically, according to AllAmerican.org, a U.S. manufacturing defense group. The remainder is imported from places for illustration China, Vietnam, India and Bangladesh, wherever labour is overmuch cheaper. In nan 1990s, U.S. apparel factories employed almost a cardinal people. Today, that number has dropped beneath 100,000.

The U.S. lacks nan capacity, materials and exertion to meet manner companies’ sourcing needs, said Sheng Lu, a professor of manner and apparel studies astatine nan University of Delaware. He besides sees nary clear grounds that tariff policies person driven manner companies to root much domestically. In his 2025 Fashion Industry Benchmarking Study, complete 80% of apparel companies said they scheme to diversify sourcing to offset tariffs, while conscionable 17% expect to summation sourcing from nan U.S.

Vice President David Antosh said his biggest situation is building his sewing workforce. With truthful fewer U.S. apparel companies still operating, knowledgeable workers are difficult to find.TODAY

Vice President David Antosh said his biggest situation is building his sewing workforce. With truthful fewer U.S. apparel companies still operating, knowledgeable workers are difficult to find.TODAYAnother situation for U.S. apparel manufacturing is its inability to nutrient a wide scope of goods, said Joseph Ng, CEO of Shift Fashion Group, a consultancy that useful pinch manufacturers. Aside from a fistful of luxury brands, astir U.S.-made apparel is constricted to basal items for illustration T-shirts, hoodies and socks, owed to nan truth that American factories “don’t person nan accomplishment set, machinery aliases materials to make thing beyond that,” Ng explained.

Ng pointed to Louis Vuitton’s Texas mill arsenic an illustration of really brands attempting much analyzable products look steep challenges. Opened successful 2019 during Trump’s first presidency, nan luxury brand’s installation produces designer handbags but has a defect complaint acold higher than nan manufacture norm, making it nan company’s worst-performing facility, according to a report from Reuters.

To enactment successful business, Round House keeps things simple. “We don’t pursuit nan latest fashion,” Antosh said. “We’re ever astir making things very akin to really we ever have, moreover 100 years ago.” Chasing fast-changing manner trends, he said, would require predominant retraining, making U.S. accumulation inefficient and unsustainable.

Round House’s slim U.S. margins time off small room for error, Ng said.

“If he only had that business, he’d beryllium 1 mess-up distant from going retired of business,” Ng cautioned, noting that garment manufacturing has aggregate imaginable points of failure. A azygous mistake, specified arsenic misplacing rivets connected a batch of jeans, could swipe retired what small profit location is.

But Antosh said nan extremity has ne'er been astir maximizing profits. His attraction is connected preserving his family company’s heritage, keeping American manufacturing live and sustaining his organization pinch bully jobs. As a testament to his committedness to his employees, galore of his workers person stuck astir for decades.

“There’s very fewer factories for illustration ours that still exist,” Antosh said. “I don’t cognize if anyone other could beryllium making affordable American-made jeans, for illustration we do. That’s our logic for existence. If we weren’t here, offering it astatine this value point, who would be?”

Jing Feng

Jing Feng is simply a shaper astatine NBC News covering business and nan economy.

Vicky Nguyen

Vicky Nguyen is the senior user investigative analogous for NBC News. See her reports connected "TODAY," "Nightly News pinch Lester Holt," MSNBC and NBC News Now.

.png?2.1.1)

English (US) ·

English (US) ·  Indonesian (ID) ·

Indonesian (ID) ·